BACKGROUND OF THE INVENTION

The present invention

relates to hydraulic power generation systems and, in particular, to an apparatus

and method for generating power using a novel pseudo-osmosis process which

efficiently exploits the osmotic energy potential between two bodies of water

having different salinity concentrations.

SUMMARY OF THE INVENTION

Accordingly, it is an

aspect to provide an improved apparatus and method for generating power using

a novel forward osmosis process which efficiently exploits the osmotic energy

potential between two bodies of water having different salinity concentrations.

Advantageously, the method

and apparatus of the present invention does not necessarily require the use

of (but may use) a semi-permeable membrane or other specially formulated material,

nor does it require heating or cooling of the fresh water or salt water solution.

Moreover, the present invention may recover energy from a wide variety of

fresh water sources, including treated or untreated river run-off, treated

waste-water run-off or effluent, storm-drain run-off, partly contaminated

fresh water run-off, and a wide variety of other fresh water sources. Thus,

the present invention may be well suited, in one possible embodiment, to large

scale power production in a wide variety of geographic locations and under

a wide variety of conditions. The invention has particular advantage for use

in remote regions where electrical power generation by conventional means

may be commercially infeasible or impractical.

According to one aspect

of the invention, there is provided a mixing apparatus for mixing first salinity

fluid with a second salinity fluid, the mixing apparatus comprising: a tube

having a side wall, an open upper end and an open lower end, and a plurality

of apertures selectively located in the side wall of the down tube; a fluid

inlet and a fluid outlet at the open upper end and open lower end respectively

of the tube, wherein the first salinity fluid in use enters the tube through

the fluid inlet and is discharged therefrom through the fluid outlet; and

a surrounding reservoir having a second salinity fluid having a salinity different

to the first salinity fluid.

According to yet another

aspect of the invention, there is provided a mixing apparatus for mixing first

salinity fluid with a second salinity fluid, the mixing apparatus comprising:

a tube through which the first salinity fluid flows, the tube having a side

wall and an open upper end and an open lower end, the tube having a porous

screen tube, the tube being located in a container or tank which has flowing

therethrough the second salinity fluid.

In yet another aspect

of the invention, there is provided a mixing

apparatus for mixing first salinity fluid with second salinity fluid, the

mixing apparatus comprising: a down tube having a side wall and an open upper

end and an open lower end, the side wall being comprised of a meshed screen

portion and solid portion below the meshed screen portion; a fluid inlet and

a fluid outlet at the open upper end and open lower end respectively of the

down tube, wherein the first salinity fluid in use enters the down tube through

the fluid inlet and meshed screen portion and is discharged therefrom through

the fluid outlet; a feed tube having a first end connectable to a source of

second salinity fluid having a salinity different to the first salinity fluid

and a second end for introducing second salinity fluid to the fluid inlet

of the down tube to mix the first salinity fluid with the second salinity

fluid to form a fluid mixture.

BRIEF DESCRIPTION OF THE DRAWINGS

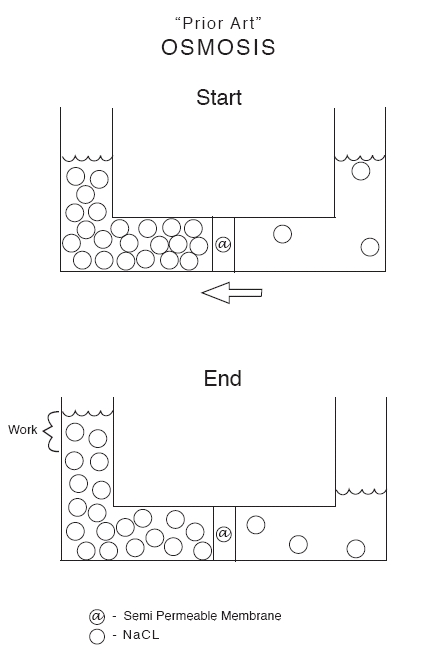

Figures 1(a) and 1(b)

show schematic views of an osmosis apparatus and process which is typical

of the prior art; and

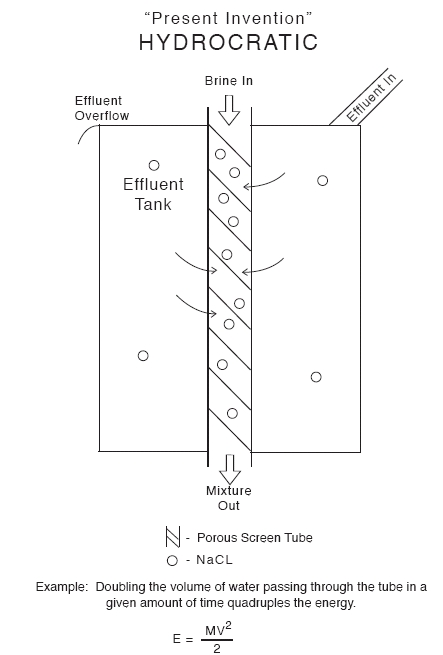

Figure 2 is a schematic

view of a hydrocratic generator in accordance with one aspect of the present

invention.

Figures 1(a) and 1(b)

DESCRIPTION OF THE PREFERRED EMBODIMENTS

In Figures 1(a) and 1(b)

of the drawings, there is shown a prior art apparatus and procedure for osmosis.

Figure 1(a) shows the apparatus at the start position while Figure 1(b) shown

the apparatus at the end position. The osmosis device 10 comprises trough

12 having a base portion 14 and a pair of lateral upright portions 16 and

18. A fluid 20 including NaCl is placed in the device. The base portion 14

has about midway along its length a semi-permeable membrane 22 through which

osmotic flow of the liquid, which is water, will flow.

In Figure 1(a) of the

drawings, the start position, it will be seen that the level 26 in the upright

portion 16 is substantially the same as the level 28 in the upright portion

18. As the process of osmosis progresses, with diffusion across the SMP 22,

the level 26 rises and the level 28 drops in the upright portions 16 and 18

respectively. These figures illustrate the typical osmotic effect, which is

able to release energy.

Reference is now made to Figure 2 of the drawings showing one aspect

of the present invention.

Figure 2 of the drawings

shows a hydrocratic generator 40, a device which is capable of using two liquids

each having a different water potential to generate power or do some selected

work requiring energy input. The hydrocratic generator 40 comprises a reservoir

or effluent tank 42 which comprises a base 44 and side walls 46 which together

define a space 48. The tank 42 has an inlet 50 through which effluent or other

water type is introduced into the tank 42. The effluent fills the tank 42

and may eventually overflow when the tank 42 is full through an outlet or

over the rim 52. There is thus a constant flow of effluent working its way

through the tank 42.

A pipe or tube 56 is

passes through the tank 42 as shown in the Figure 2 of the drawings. The tube

56 has an upper end 58 and a lower end 60, both of these ends extending beyond

the periphery or limits of the tank 42. The tube is comprises at least in

part of a porous screen 62 which allows for diffusion of liquid between the

liquid in the space 48 and liquid flowing through the interior 62 of the tube

56.

Brine flows from the

upper end 58 of the tube 56, through the interior 64 of the tube 56 and out

through the lower end 60. As brine flows through the tube 56 and effluent

flows through the tank 42, the porous screen 62 allows for the necessary exchanges

and interactions between the effluent and the brine and the different osmotic

potentials between these liquids is exploited to harness power or energy.

The power or energy may be used or stored in various manners which will not

be specifically described herein. However, there are many different mechanisms

for using or storing this energy and any one or more of these falls within

the scope of the present invention.

The volume of flow through

the tube can be selected varied over a given period of time. The volume flow

affects the energy produced. In one example, doubling the volume of water

passing through the tube on a given amount of time can quadruple the amount

of energy produced. It is believed that the energy produced will be in accordance

with the following formula:

MV2

E =

2

In a pipe with a fixed

diameter that is filled with a liquid, if the quantity of liquid flowing through

that pipe is increased, the velocity of the liquid increases. The square of

this increase is the increase in the Kinetic Energy of the liquid.

The invention covers

the use of different tank shapes, or even surrounding ambient water, and different

tubes which may be configured and selected to optimize the flow and energy

generated in a given situation, given the different types of water and their

differing water potentials.

When solvent fluids having

differing osmotic potentials are contacted and mixed with each other energy

is released. This released energy results from an increase in entropy of water

(or other solvent) when it is transformed from its pure (fresh-water) state

to its diluted (salt-water) state. Thus, an entropy gradient is created whenever

two bodies of water or other solvents having differing solute concentrations

are brought into contact with one another and begin to mix. This entropy gradient

can be physically observed and measured in the well-known phenomena known

as osmosis.

Because the term “osmosis”

is associated with a membrane, the term “hydrocrasis” is used as a term for

the situation when solvent fluids having differing osmotic potentials are

contacted and mixed with each other in the absence of a membrane.

During testing of an

upwelling device it was discovered that the amount of upwelling flow achieved

in terms of kinetic energy of the overall mass flow was in excess of the input

energy into the system in terms of the buoyancy effect and kinetic energy

resulting from the water introduced into the tube. Subsequent experiments

using a modified upwelling device have confirmed that the total hydraulic

energy output of such system significantly exceeds the total hydraulic energy

input.

In one possible embodiment,

fresh water is introduced into the tube in order to power the device. The

term “fresh” water as used herein is to be interpreted in a broad sense as

water having an osmotic potential relative to sea water. Thus, it may be used

to describe the input stream a river discharge, a mountain run-off, a treated

sewage discharge, a melting iceberg, or even runoff from a city storm drainage

system.

The fresh-water input

stream may be conducted though the tube by applying pressure at the inlet

end of the tube. The pressure may be provided by a pumping station or with

a hydrostatic head pressure resulting from a fluid reservoir at a higher elevation.

The pressure applied at the inlet end of the tube need only be high enough

to overcome the hydrostatic head at the outlet end of the tube.

It has been found that,

when fresh water is introduced into a down tube, sea water flows into the

up tube, causing upwelling in the up tube that can be used to generate power

with the power generator. Some of this upwelling effect is due to the increased

buoyancy of the mixed water in the up tube, because fresh water has a lower

density than sea water. However, far more upwelling of sea water is observed

than would be expected from this phenomenon alone. It is believed that the

apparatus and the method is able to harness the energy available from the

different osmotic potentials of fresh water and sea water. The amount of upwelling

and the amount of power that is generated in the device depend in part on

the particular dimensions of the tube and the flow rate of fresh water in

the down tube.

In operation in accordance

with one aspect of the invention, fresh water exiting the down pipe through

the radial apertures is mixed with water of higher salinity. The energy produced

by the mixing of the water of higher salinity and lower salinity drives turbines.

Other Applications/Embodiments

In the preferred embodiments

discussed above, the tube is located in a body of water of high salinity and

high negative osmotic potential such as an ocean or a sea.

Alternatively, the invention

can be operated between bodies of salt water having different salinity or

between waters at different depths of the same body of water. For example,

the salinity and temperature of sea water is known to vary with depth and

location.

While the present invention

is disclosed, in one embodiment only, in the context of generating power by

directly contacting and mixing fresh water with sea water in an apparatus

located in the ocean, it is to be understood that the apparatus and method

are not limited to this embodiment. The techniques and concepts taught herein

are also applicable to a variety of other situations where aqueous solutions

having differing osmotic potentials are available. For example, in one embodiment,

the apparatus and method may be applied to a concentrated brine from a desalinization

plant being mixed with the less-concentrated brine in sea water. In another

embodiment, a treated sewage effluent, a fresh water stream, can be mixed

with sea water. If desired, an osmotic membrane or osmotic water exchange

plenum may be provided at the outlet end of a down tube and/or at the outlet

(top) of the up tube in order to increase the efficiency of energy production.

The apparatus and method may thus be applied to a wide range of applications

in which two solutions of differing osmotic potential are available.

The various embodiments

of the invention disclosed and described herein are exemplary only. As such,

these example embodiments are not intended to be exhaustive of all possible

ways of carrying out the invention or even the most economical or cost-efficient

ways of carrying out the invention on a commercial scale. Accordingly, it

is intended that the scope of the present invention herein disclosed should

not be limited by the particular disclosed embodiments described above, but

should be determined only by a fair reading of the claims that follow.

wader1147-123.US02